| The idea is simple |

| This car was built using some scrap aluminum stock, about $20 worth of hardware from Microfasteners, and wheels from Ozark Miniatures. |

| The tipper can dump to either side of the track. It is stable when empty or full yet dumps easily and empties completely. |

| The tipper was made from large (4" leg x 1/8" thick) aluminum angle and 1/16" plate. the rivets were embossed into the plate with a gromet press from a fabric store. |

| The wheels came on gauge one (45 mm) axles. David turned new axles for them out of 1/2" drill rod. They have dual bronze bearings to negotiate very tight radius track. |

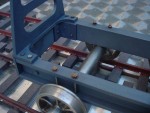

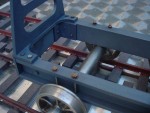

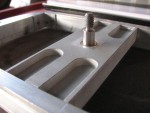

| Close up of the frame. The aluminum channel was cut to profile on a table saw. The axles are securely attached to the frame with hand made miniature U-bolts. |

| Top view of the frame. Everything is bolted together with 2-56, hex-head, screws. |

| Side view. |

| The plan is to make a locomotive to go with these mine cars. I will then look into making other, more unique, mining equipment in the same scale. |

| The parts are nearly ready to make a second car. |

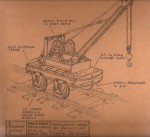

| Complete drawings |

| Installed wheelset |

| parts |

| As you can see the mine car now has real charachter after a weathering job |

| Rusty but trusty. |

| The display track is made from LGB rail hand spiked to cherry wood ties. |

| The Sierra Valley wheels look good rusted. They are free rolling thanks to the bronze bearings. |

| Speaking of 1" scale. The Amerikrauss 0-4-0 sits on a siding near the mine car. |

| Comparison of a 1:20.3 scale ore car to the 1" scale ore car. |

| This is a hint of the next 1" scale project! |

| A one-evening project. The frame for the next mining car is complete. This time it's a flat car that is going to serve as a boom car for the crane that I (Eric) am building next. In the back ground is the original full size drawing. |

| The new Sierra Valley curly spoke wheels were re gauged by David to 3.5". |

| The frame is mortised together and there is no glue. The truss rods hold it together with tension. The coupler pockets are 1:13.7 scale from Ozark Miniatures but work well with 1:12 scale. |

| The 1:12 scale car compared to a 1:20.3 scale car. |

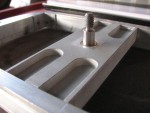

| To make track for these mine cars, a milled aluminum drill jig is used to locate pilot holes in the wooden ties. This allows you to spike down code 332 rail. For the display track, miniature spikes were individually hand made. |

| The winch has been assembled for the crane car. |

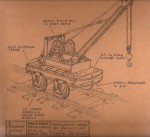

| Concept sketch for the crane car. |

| Isometric drawing of the crane car. The next 1:12 scale project! |

| The flat car is done (except for a little weathering.) |

| The steel bars that are laminated to the underside of the deck provide weight and allow cargo to be secured to the deck with magnets. |

| DSC03332.JPG |

| DSC03328.JPG |

| Another comparison. 1:12 vs. 1:20.3 |

| The train is gradually forming. Next is the crane car. |

| A little distraction before working on the crane. Time to work on the second ore car. Here are the double bearing axle components. |

| The frame is assembled. |

| Here are the hand made miniature U-bolts that secure the axles to the frame. |

| The tipper supports are finished but still need to be bolted to the frame. |

| The chassis is rolling and fully assembled. The raw aluminum is still covered in layout markings. |

| Tipper pivots: installed. |

| links from a length of chain and nails with the points ground off = cheap links an pins for coupling the cars together. |

| My train is taking shape! |

| Almost a year later I am working on the crane again. This car features a metal frame like the ore cars but it is outside frame. |

| This heavy cross-member is made from 1/2" thick aluminum plate. It has a bronze bearing pressed into the center for the gantry pivot. |

| The gantry is partially assembled. The supports for the boom have not yet been resolved. |

| A counter-weight was made from 3/8" plate. It was secured to the gantry with 1-72 screws. |

| The boom is mounted to the gantry with Ozark Miniatures axle supports. The rivets that are on the frame are called "drive screws" You just pound them into a pre drilled hole. |

| The hook was built up from a brass ball, flat bar, wire, and a turned pulley and axle. |

| Many of the parts were sandblasted to give them the appearance of castings. |

| Here is the crane mocked up. After a discussion with David and Henner I decided that the gantry needed to be raised up on a pedestal to make it more "user friendly". |

| In about a week I was able to resolve many of the issues and get the car finished. |

| The gantry is now a better height on a large pedestal made from a length of copper pipe and brass plate. |

| With the exception of the winch kit this car is 100% bolted together with scale hardware. |

| The base of the pedestal is visible. Notice the the scale diamond plate. this is a product from O.S. Engines of Osaka Japan. |

| The crane has a very short wheel base of only 4". it is just 1/2" longer than the track gauge. |

| To give the frame that rounded look that small industrial cars have, I used the full depth of the aluminum channel on the car ends. The curvature was sanded to shape with a large belt sander. |

| Grab handles made from ordinary steel bailing wire were added to the gantry. They are bolted in place. I still need to add a ratchet to prevent the winch from unspooling. |

| This is solution I came up with to support the boom. |

| The boom supports can be disconnected by the two lobster clips and the boom can be lowered. |

| The rope is routed over some modified Ozark Miniatures pulleys. |

| The underbelly of the crane is very simple. Visible are the heavy cross-member, the gantry pivot screw, and the four small screws and nuts that hold the pedestal in place. |

| DSC02597.JPG |